Technical Articles

The Working Process of ABS Plastic Electrolysis

Writer: admin Time:2024-06-25 13:36:11 Browse:288℃

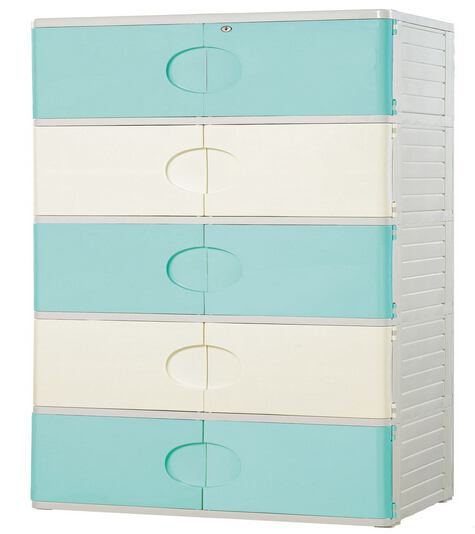

ABS plastic electrolytic is the most important technology, so let's introduce the working process of ABS plastic electrolysis and things need to be aware of. When there are too many rubber particles after the coarsening, small pit becomes bigger and lack of binding force. If there is more polycarbonate, organic solvent is needed for pre-coarsening. ABS plastic storage locker is terpolymer of (A) acrylonitrile and (B)butadiene and (S)styrene, and mixture of resin phase composed of acrylonitrile and styrene and elastomeric phase (also known as the rubber phase)composed of styrene and butadiene. Then, PC (polycarbonate) is added in the ABS to improve the function.

Whether plastic parts is suitable for plating depend on plans of plastic parts. Dissolving rubber particles to small hole makes the metal fade away, and it is the foundation of layer binding force. When it comes to attachment, there is no need to choose metal material and it should not be too thin and abrupt thickness. Process: distressing - chemical degreasing - hydrophilic - chemical coarsening - back - neutralize - presoak - colloid palladium activation - back - peptize - chemical nickel - activation solution(5% hydrochloric acid) - focal copper - acid copper - bright nickel - chromium, therefore, the content of butadiene (B) should be controlled within 18% - 23% in the ABS used for electroplating. And only when ABS is closed to the clad layer of copolymerization, can binding force be good. When there are not enough rubber particles, pit will be fewer, and binding force will be poor after the coarsening. It is a little bit more difficult to coarsen after adding PC. When PC is up to 40%-45% (mass fraction), roughening solution of ABS can still be used for coarsening, no need to use organic solvent for pre-coarsening, and simply coarsen 15 minutes at 68 degrees. Groove and hole should not be too close and the side should be round. The ABS that meeting the requirements above is called electroplating ABS, the most suitable for plating.

CATEGORIES

LATEST NEWS

CONTACT US

Tel: 400-138-0592

Email: sales@topplagroup.com

Add: No. 5 Nantang Road, Guankou Town, Jimei District, Xiamen City Postal